WHAT DOES “NEXT GENERATION HELMET TECHNOLOGY” ACTUALLY MEAN?

Next Generation Helmet Technology refers to a helmet that provides a consistent level of performance at a much lighter weight, under more extreme conditions, and for longer periods of time.

The U.S. Army defined in its recent helmet’s requirements, the AR/PD 14-01, also known as “ACH GEN II”, that specific performance requirements and testing protocol be attained to ensure the helmets they utilize meet their definition of “ACH GEN II”. More armies and police organizations worldwide have followed suit and now define these parameters as mandatory.

A TRUE Next Generation Advance Helmet MUST uphold and perform in ALL of the below categories / elements:

- IMPROVED PERFORMANCE

- REDUCED WEIGHT

- EXTREME CONDITIONS

- AGING / LONG PERIODS RESISTANCE

GEN II PERFORMANCE

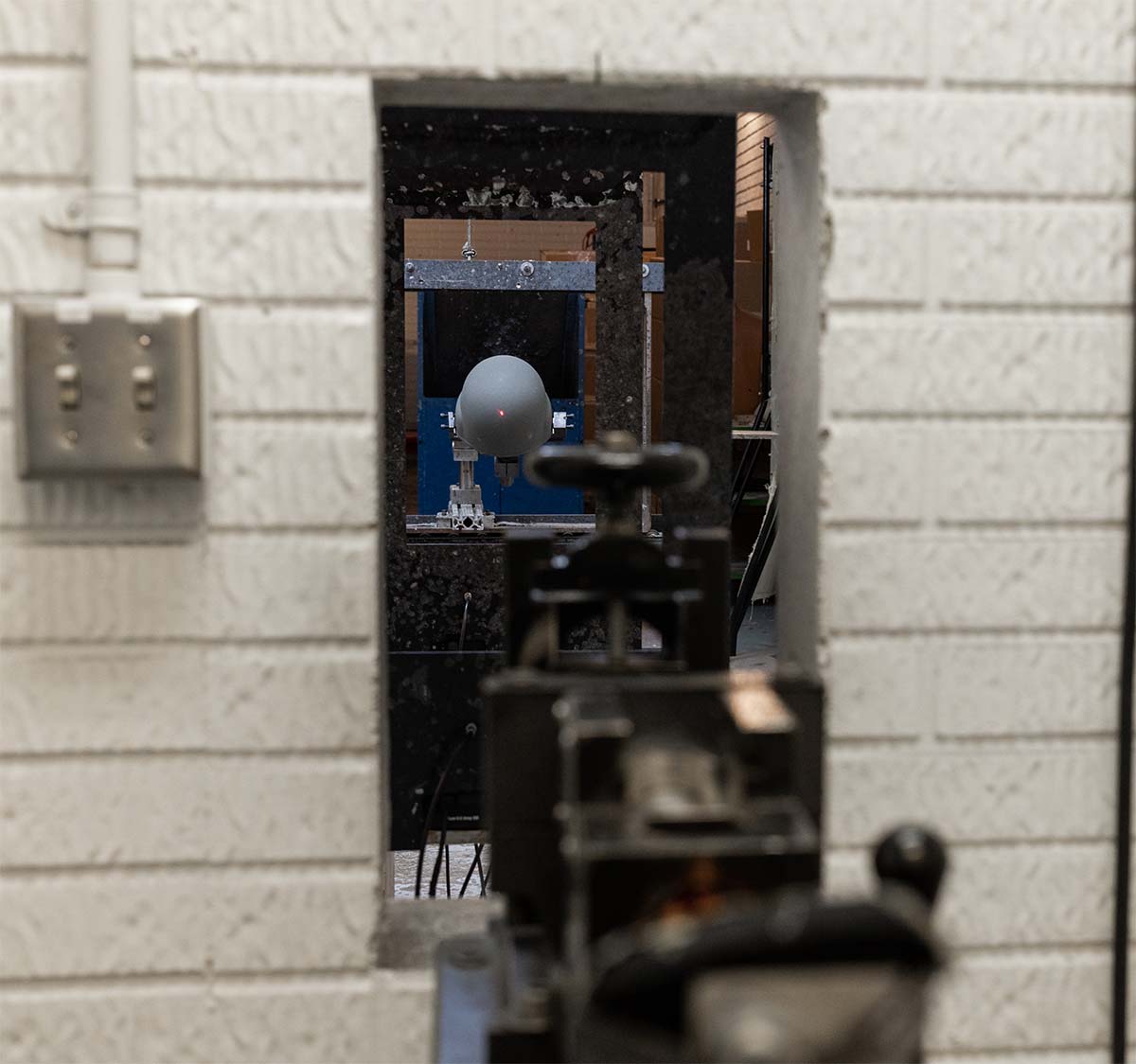

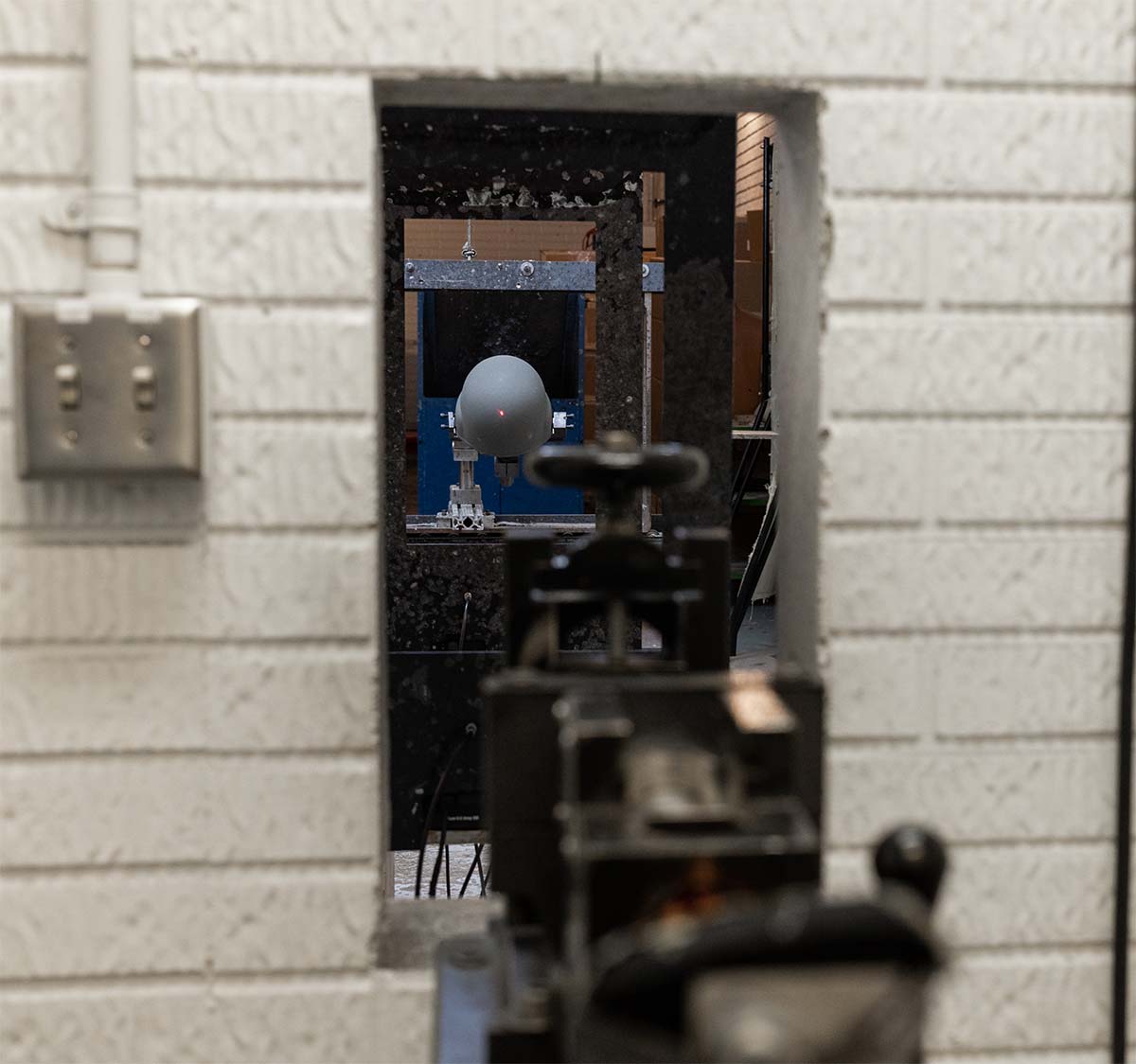

Ballistic Threats

ArmorSource GEN II solutions uphold both, AR/PD 14-01 AND NIJ IIIA requirements, which include:

- Defeats arms from handguns to rifles, by providing consistent and lasting ballistic protection.

- Trauma – 9 mm BFD Up to 1” (25.4 mm)

- As most of the ballistic incidents in the battlefield are originated by explosions, such as artillery, side charges, grenades, and mines, a GEN II helmet must provide protection against a wide spectrum of high velocity fragments and handgun projectiles.

V50 Values

| 17 Grain | > 750 m/s |

| 4 Grain | > 1,220 m/s |

| 64 Grain | > 650 m/s |

| 2 Grain | > 1,400 m/s |

| 16 Grain | > 770 m/s |

Environmental and Mechanical Threats

Based on recent research, most injuries sustained during activity are associated to non-ballistic incidents. Therefore, A Gen II helmet must provide a consistent and lasting protection against the below environmental and mechanical threats:

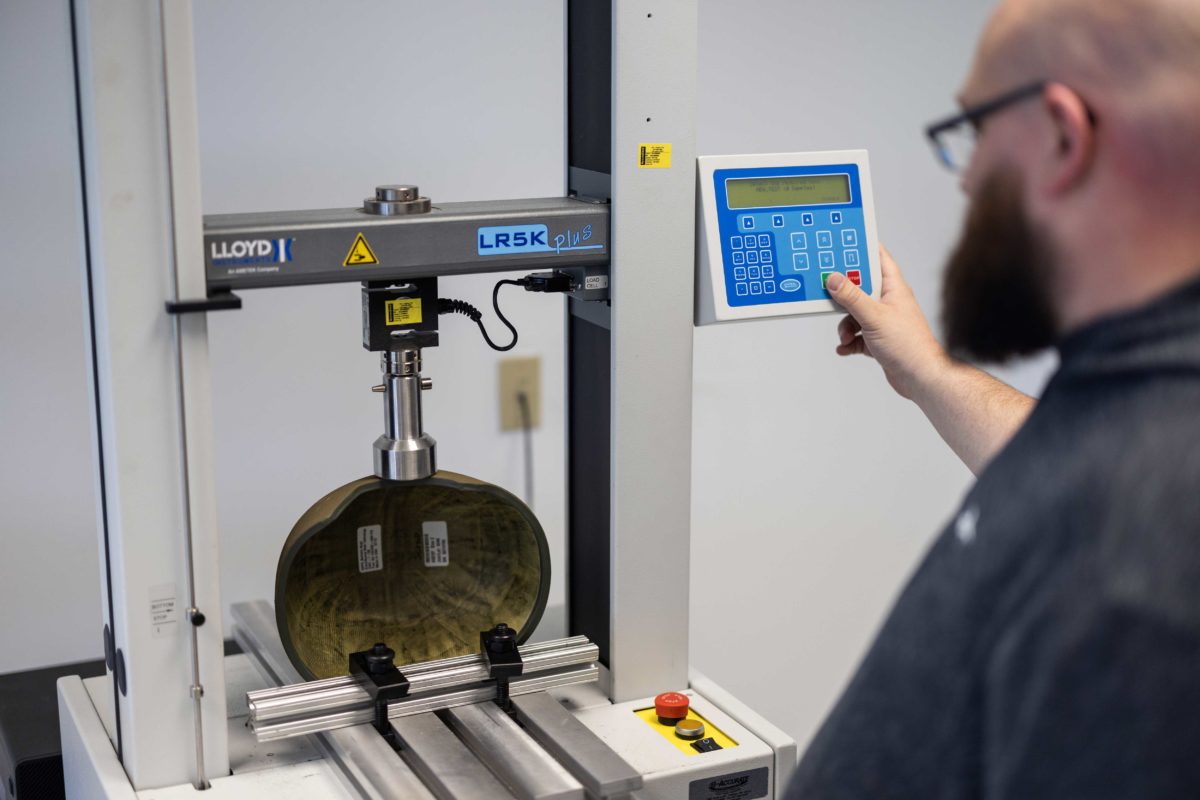

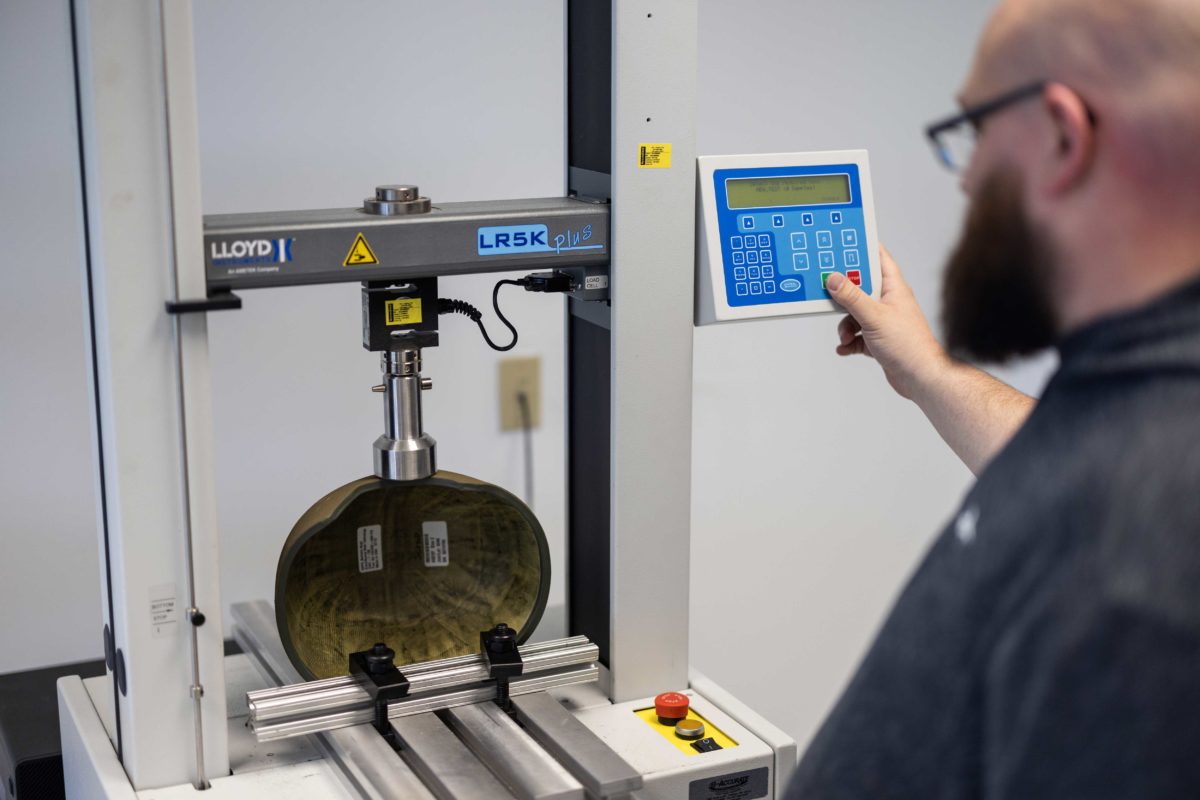

- Blunt Impact – The helmet system must be able to sustain a direct hit of a heavy, high velocity blunt object that impacts the shell.

- Compression Resistance – The helmet must defeat a high level compression from side to side and top to bottom.

- Flammability

- Water Absorption

GEN II WEIGHT

Weight is a Major Element Within Next Generation Helmet Requirements

GEN II Helmets must be tested and perform perfectly, at a significantly reduced weight, reflecting up to 40% weight reduction versus Aramid based solutions that provide similar performance.

ArmorSource Next Generation Shells are designed to meet ALL GEN II requirements at an areal density of below 6.9Kg/m2 (1.38lbs./f2).

ArmorSource Gen II Helmet System Weight

Full cut with Harness and Pads

| Med | < 1,010 g. |

| Large | < 1,080 g. |

| X-Large | < 1,130 g. |

High-cut with Harness, Pads, Rails and Shroud

| Med | < 1,000 g. |

| Large | < 1,075 g. |

| X-Large | < 1,120 g. |

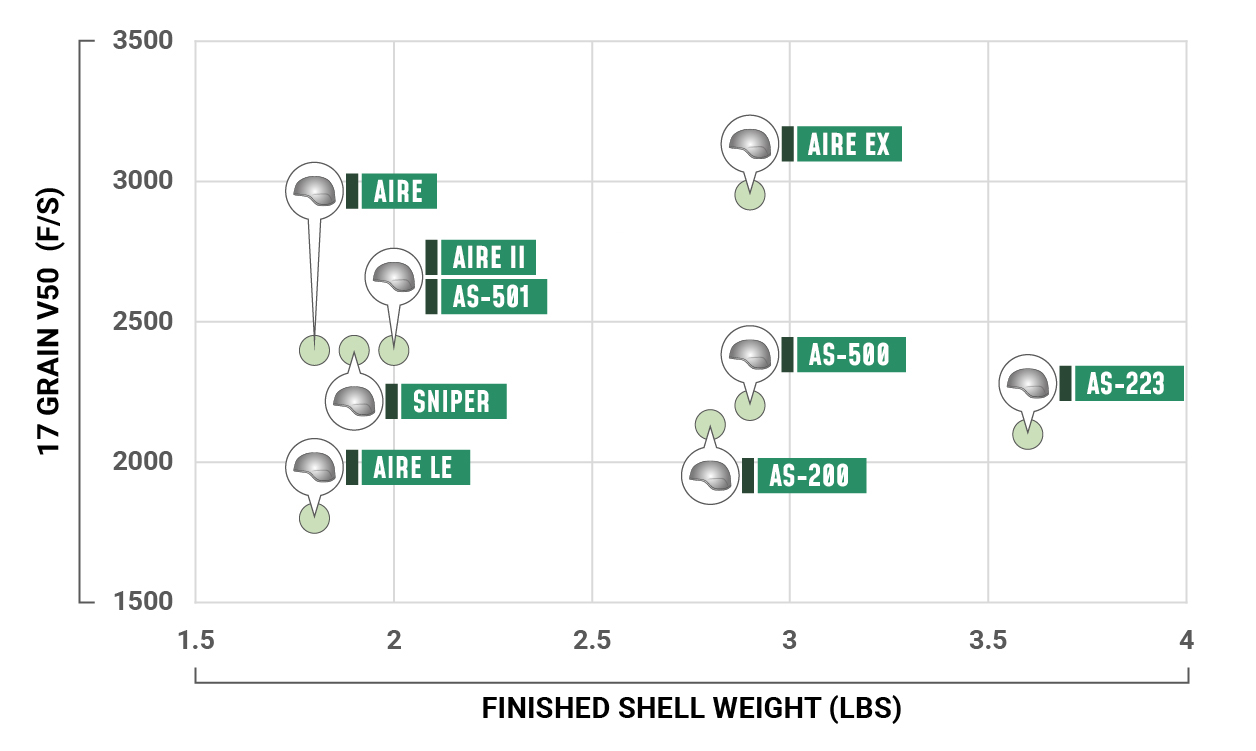

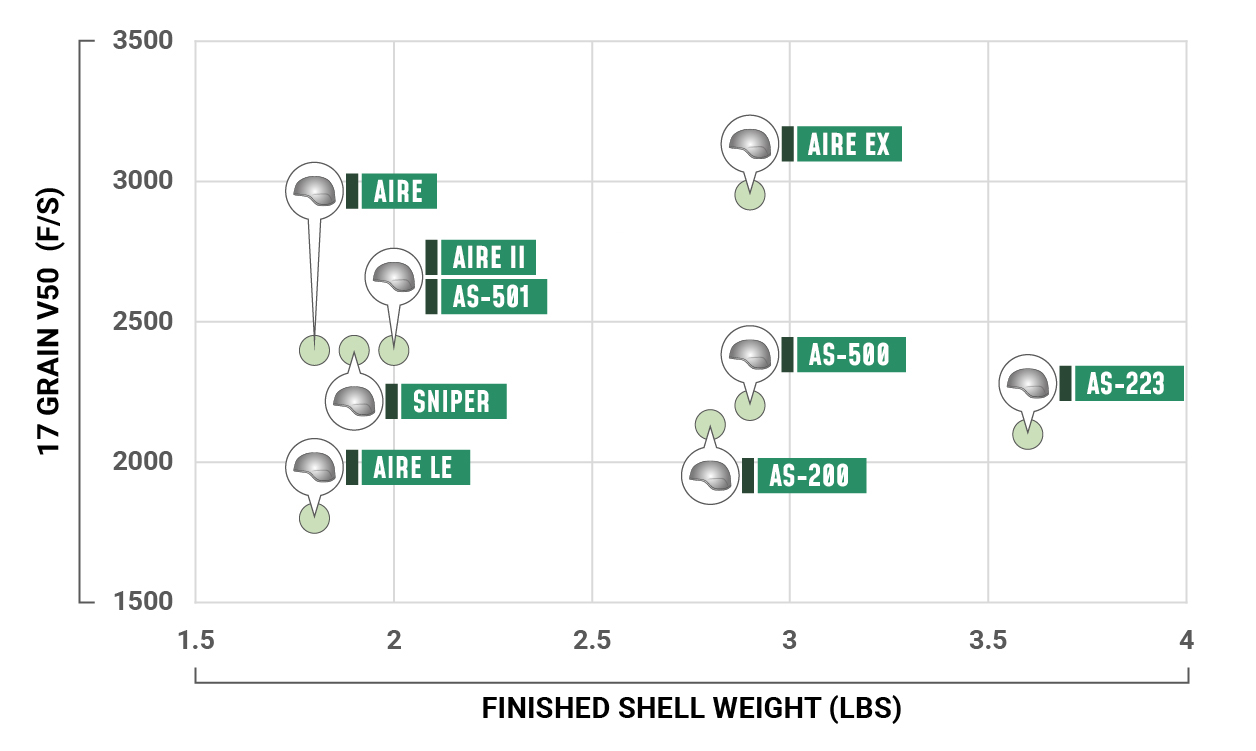

GEN II BALLISTIC EFFECTIVENESS

In an effort to protect the world’s most demanding users, we aim to maximize ballistic performance while minimizing weight. Below you can compare the effectiveness of our products side by side.

* Finished helmet, Full cut.

** IAW U.S. Army AR/PD 14-01

GEN II CONDITIONS

Exposure to Conditions

A Gen II helmet must meet all the performance requirements above, even after being exposed to extreme conditions. All Gen II helmets must perform in the following conditions.

- Extreme Heat – The helmet must be tested and meet performance requirements after being exposed to a temperature of 71°C (160°F).

- Extreme Cold – The helmet must be tested and meet performance requirements after being exposed to a temperature of -51°C (- 60°F).

- Saltwater – The system must be tested and meet performance requirements after being immersed in salt water for a predetermined duration of time.

- Field Agents – The helmet must show resistance to common liquids and field agents such as diesel, gasoline, fuel, oil, paint, etc.

- Vibration – The entire system must be tested and meet performance requirements after being exposed to what is defined as a “Massive Vibration”.

- Altitude – The helmet must be tested and meet performance requirements after being exposed to an environment reflecting 40,000 ft altitude at a temperature of -52°C (-62°F).

- Temperature Shock – The helmet must be tested and meet performance requirements after being exposed to extreme temperature shock; hot to cold, and cold to hot.

GEN II Aging

Also known as Long Periods Resistance:

To make sure the helmet meets its performance requirements over time, it must also be resistant to aging. ArmorSource Next Generation Helmet Shells maintain performance requirements between eight to ten years in active use.

Testing Methods:

- Weatherometer – The helmets must be tested and meet performance requirements after being exposed to extensive Weatherometer cycles.

- Accelerated Aging – The helmets must be tested and meet performance requirements after being exposed to extensive Accelerated Aging cycles.